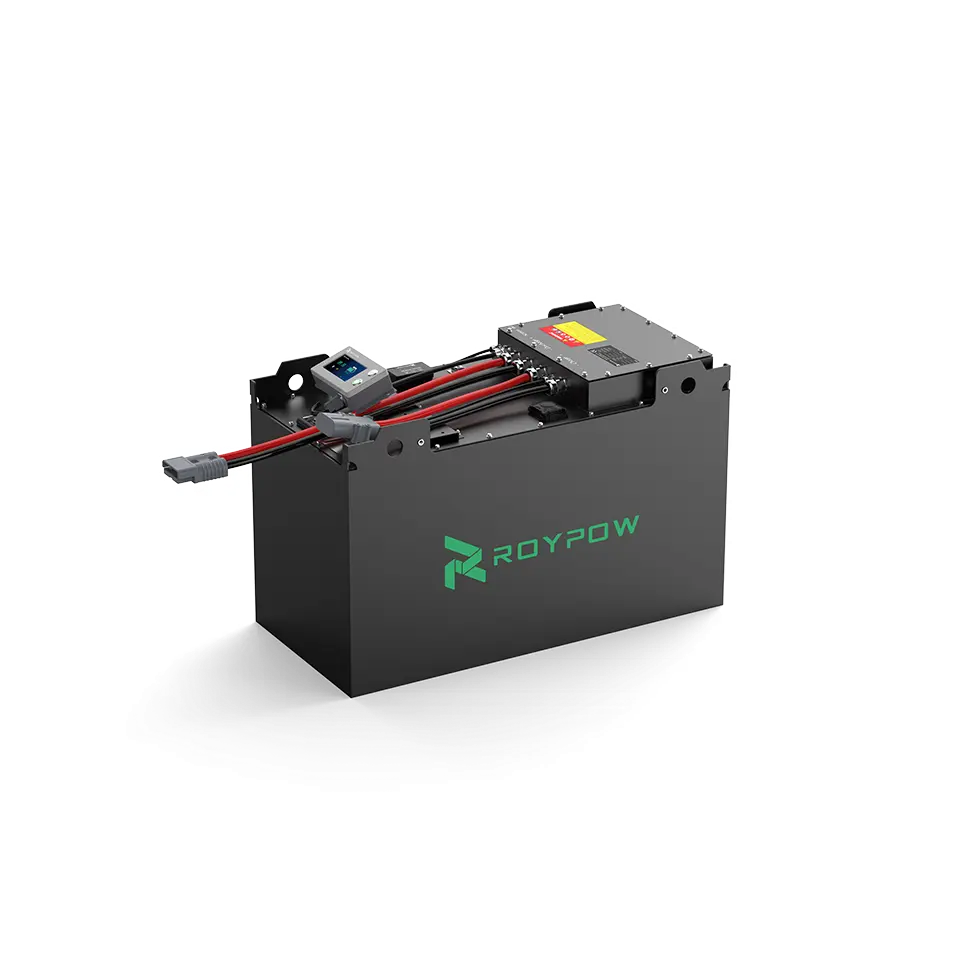

With an emphasis on quality and innovation, ROYPOW offers dependable electric forklift batteries to companies, increasing productivity and efficiency in material handling operations. Businesses can see notable gains in productivity and overall performance by investing in ROYPOW’s lithium forklift batteries.

Understanding Forklift Battery Weight

When considering forklift batteries, it is crucial to understand their weight and how it affects equipment stability. ROYPOW lithium forklift battery is designed with high capacity and robust construction, resulting in a substantial weight to support demanding industrial applications. This substantial weight is designed specifically for optimal performance and safety. Before installing any new or different forklift battery, operators must check both the forklift nameplate and the battery’s service weight to ensure compatibility. Using a forklift battery that is not suited for the equipment can ultimately change the center of gravity and lead to potential safety hazards, such as equipment upsets.

Hassle-Free Maintenance with Lithium Technology

One of the most significant advantages of ROYPOW’s lithium forklift batteries is that they completely eliminate the need for water filling, a common maintenance requirement for traditional lead-acid batteries. This simplifies the upkeep process for electric forklift batteries, allowing operators to focus on their primary tasks without the added concern of maintaining water levels. For lead-acid batteries, water should be added only after full charging to prevent overflow; however, with lithium forklift batteries, this worry is non-existent, providing peace of mind to operators.

Conclusion

In conclusion, ROYPOW’s lithium forklift batteries are transforming the landscape of material handling. By understanding the importance of battery weight and enjoying the hassle-free maintenance that comes with lithium technology, businesses can enhance their operational safety and efficiency. Investing in these advanced electric forklift batteries ultimately leads to improved productivity and a competitive edge in today’s dynamic market.